Mastering Mast Stability: The Essential Role Of Guy Wires

In the world of towering structures, from communication masts to amateur radio antennas, stability isn't just a preference—it's a critical necessity. Without proper support, these vertical giants are vulnerable to the relentless forces of nature, particularly wind and seismic activity. This is precisely where the unsung heroes of structural integrity, the guy wires, come into play, providing the crucial lateral bracing that keeps everything firmly in place.

- African Mammal With Striped Legs

- Island Grille

- Envision Credit Union

- Incredible Hulk Grey Hulk

- Eddie Murray

Often overlooked but undeniably vital, a well-designed and properly installed guy wire system transforms a potentially precarious structure into a robust and reliable fixture. Whether you're an amateur radio enthusiast, a professional in telecommunications, or simply curious about how tall structures defy gravity, understanding the intricate role of guy wires is fundamental to appreciating their engineering brilliance and the safety they provide.

Table of Contents

- What Exactly is a Guy Wire? Understanding the Fundamentals

- The Unseen Force: Why Guy Wires are Indispensable for Tall Structures

- Anatomy of a Guyed System: Components and Their Purpose

- Installation Best Practices: Ensuring Safety and Performance

- The Convenience of Tilt-Over Systems: A Practical Application

- Addressing Potential Issues: From RFI to Design Flaws

- Longevity and Maintenance: Keeping Your Guy Wires Strong

- Conclusion

What Exactly is a Guy Wire? Understanding the Fundamentals

At its core, a guy wire is a tensioned cable, rope, or rod designed to add stability to a free-standing structure. Unlike a simple wire rope, which might be used for lifting or pulling, guy wires are specifically engineered to counteract lateral forces, pulling against the structure to keep it upright and plumb. Imagine a tall flagpole; without any external support, a strong gust of wind could easily bend or snap it. Add three or four guy wires anchored to the ground, pulling in different directions, and the flagpole becomes remarkably resilient.

The fundamental principle behind guy wires is triangulation. By connecting a point on the structure to a point on the ground, a stable triangle is formed. Multiple such triangles, arranged radially around the structure, create a robust support system. While often appearing simple, the engineering behind these systems is quite sophisticated, involving calculations for wind loading, material strength, and proper tensioning. The specific type of wire used is crucial; for instance, EHS (Extra High Strength) guy wire has a different twist than standard wire rope, and requires preforms made for that specific type of wire to ensure secure and lasting connections. This distinction highlights that not all wires are created equal when it comes to the demanding application of guying.

- Original Italian Pizza

- Nicks Rockaway

- Alamo Drafthouse Springfield

- Mike Wedding Dates

- Coconut Creek Hyundai

The Unseen Force: Why Guy Wires are Indispensable for Tall Structures

The necessity of guy wires becomes strikingly clear when considering the forces that act upon tall, slender structures. Wind, in particular, exerts immense pressure, and without adequate lateral support, even robust masts can buckle, twist, or collapse. Beyond wind, seismic activity, vibrations, and even the weight of attached equipment (like large antennas) can introduce stresses that a free-standing mast simply cannot handle on its own.

For structures like communication towers, broadcast antennas, or amateur radio masts, the reliance on guy wires is absolute. Consider the various types of antennas popular in amateur radio: Yagi, quad, rotary dipole, and LPDA (Log-Periodic Dipole Array) antennas. These often have significant wind loading characteristics due to their size and shape. Mounting such an antenna on a 16ft 2" galvanized pipe attached to a factory tilt base assembly, as described in some installations, demands the additional stability provided by a well-designed guy system. Without this crucial support, the structure would not only be unsafe but also highly susceptible to failure during adverse weather conditions. In a purely aesthetic sense, some might argue that "with no guy wires, the antenna would look really ugly" – perhaps implying a sense of instability or incompleteness. However, the true ugliness lies in a collapsed mast, making the functional necessity of guy wires far outweigh any perceived visual clutter. They are the unseen force, quietly ensuring the longevity and safety of our vertical infrastructure.

Anatomy of a Guyed System: Components and Their Purpose

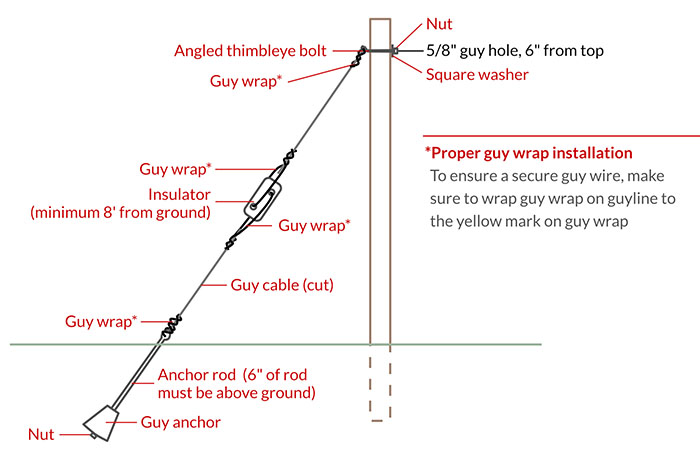

A complete guyed system is more than just a wire; it's an assembly of specialized components, each playing a vital role in the overall stability and performance. Understanding these parts is key to proper installation and maintenance.

The Guy Wire Itself: Material Matters

The choice of material for the guy wire is paramount. Steel is common, particularly EHS (Extra High Strength) galvanized steel, known for its incredible tensile strength and resistance to corrosion. As mentioned, EHS guy wire has a different twist than wire rope and requires specific preforms (or "dead ends") designed for that particular type of wire to ensure a secure and non-slip termination. Using the wrong type of fitting can lead to catastrophic failure.

However, for certain applications, especially those involving radio frequency (RF) sensitive equipment, non-conductive materials are preferred. Phillystran, a brand of synthetic fiber rope, is indeed a good product in this regard. It offers high strength comparable to steel but without the electrical conductivity. Crucially, Phillystran is "really not any more expensive than using egg insulators to break up guy" wires, making it an attractive alternative for those looking to mitigate RFI (Radio Frequency Interference) issues without adding numerous insulators to a steel guy system.

Anchoring and Attachment Points

The effectiveness of a guy wire system hinges on secure anchoring. This involves robust ground anchors and reliable attachment points on the mast itself. For mast attachments, using Rohn's guy assemblies (not torque arms) allows a secure attachment for the guys, demonstrating the importance of using manufacturer-recommended components designed for the specific mast and guy wire type. These assemblies are engineered to distribute stress evenly and prevent damage to the mast.

At the ground end, anchors must be deeply set and capable of withstanding the maximum anticipated tension. This might involve concrete footings, screw-in anchors, or heavy-duty stakes. The connection from the guy wire to the anchor often involves turnbuckles for tensioning and thimbles to protect the wire from sharp bends. In some setups, a webbing about 1" wide might be used as part of the anchor system, providing flexibility or additional load distribution at the ground level. The entire assembly, from the mast attachment to the ground anchor, must be meticulously planned and installed. As one might experience, "all the parts were there and fit correctly (with a little tweaking)," indicating that even with quality components, minor adjustments are often part of the installation process to achieve perfect alignment and tension.

Guy Rings and Spacing

Guy rings are critical components that encircle the mast, providing attachment points for the guy wires at various heights. These rings must be robust and allow for some degree of movement or rotation without damaging the mast. The guy rings are typically made of thick aluminum with a heavy plastic insert to allow the tubing to rotate freely, preventing wear on the mast material while maintaining a secure attachment point for the guy wires.

The spacing of these rings along the mast is crucial for optimal stability. A general rule of thumb often cited is "generally, one ring for each 10' of mast unless otherwise supported." This ensures that the mast is supported at regular intervals, preventing buckling or excessive sway. The exact number and placement of guy levels will depend on the mast's height, its structural design, the anticipated wind loads, and the specific equipment mounted on it. Each guy level typically consists of three or four guy wires radiating outwards to their respective ground anchors, forming a stable, multi-level support structure.

Insulators and Grounding Considerations

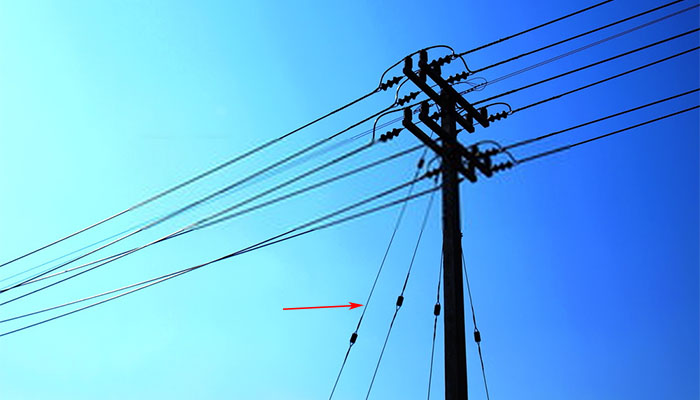

For structures that involve radio frequency (RF) transmission, such as amateur radio or broadcast antennas, the electrical properties of the guy wires become a significant concern. Metal guy wires can act as parasitic conductors, picking up or radiating RF energy, which can cause RFI (Radio Frequency Interference) or negatively impact the antenna's performance, leading to issues like high SWRs (Standing Wave Ratios).

To mitigate this, most installations use one or more insulators on each guy wire to keep the wires from becoming parasitic conductors causing RFI. These insulators, often made of ceramic (like "egg insulators") or specialized plastics, effectively break up the electrical length of the guy wire, preventing it from resonating at radio frequencies. While grounding guy wires is a complex topic, it's often not directly covered in general installation guides due to the prevalence of insulators. However, proper grounding of the mast itself and the entire electrical system remains critical for lightning protection and operational safety. The decision between using insulators on steel guys or opting for non-conductive materials like Phillystran often comes down to cost, ease of installation, and the specific RF environment.

Installation Best Practices: Ensuring Safety and Performance

The longevity and safety of any guyed structure depend heavily on meticulous installation. It begins with comprehensive planning, including a site assessment to determine optimal anchor points, considering soil conditions, underground utilities, and clear pathways for the guy wires. Accurate measurements are critical for cutting guy wires to the correct length and ensuring proper tensioning.

Proper tensioning is a science in itself. Too little tension, and the mast will sway excessively; too much, and the guy wires or mast could be overstressed, leading to premature failure. Industry standards and manufacturer guidelines provide specific tensioning values, often achieved with specialized tools. It's also important to ensure that each pole has a pulley on the top, that sustains the guy wire during installation, allowing for smooth raising and tensioning of the mast. This attention to detail, from using the correct preforms for EHS guy wire to precisely tensioning each line, is what differentiates a stable, long-lasting installation from a hazardous one. Avoiding common pitfalls like inadequate anchor depth, improper termination of the guy wires, or neglecting to use insulators where needed can prevent significant problems down the line.

The Convenience of Tilt-Over Systems: A Practical Application

While fixed guyed masts are common, tilt-over systems offer a significant advantage for maintenance and antenna adjustments, particularly for amateur radio operators. These systems incorporate a hinged base that allows the entire mast to be lowered to a horizontal position. For instance, an antenna is often mounted on a 16ft 2" galvanized pipe attached to a factory tilt base assembly. This tilt base is then mounted securely, perhaps to a 4ft concrete pad or a robust ground frame.

The beauty of such a system is the ease of access it provides. "When tilted over, the yagi hung over the gable end of the garage and was easily accessed in the driveway," illustrating how a large antenna can be safely brought down to ground level for work. This eliminates the need for dangerous tower climbing or expensive lift equipment for routine maintenance, antenna tuning, or even changing out an antenna. The process can be surprisingly manageable: "I would easily manually tilt the mast up, grab the backstay guy wire, walk it out to the..." – indicating that with a properly designed system and a bit of technique, even a single person can manage the tilting operation. Guy wires still play a crucial role in these systems, supporting the mast in its upright position and sometimes even assisting in the tilting process as backstays.

Addressing Potential Issues: From RFI to Design Flaws

Even with the best intentions and quality components, issues can arise in guyed systems. One prevalent problem, particularly in amateur radio, is RFI (Radio Frequency Interference) and its impact on SWRs (Standing Wave Ratios). As noted earlier, if guy wires are not properly insulated, they can act as parasitic elements, distorting the antenna's radiation pattern and causing SWRs to be a problem. This often manifests as poor signal transmission or reception, and can be a frustrating puzzle for operators. The solution typically involves strategically placed insulators, or, as discussed, the use of non-conductive guy materials like Phillystran.

Beyond RF issues, structural problems can emerge, sometimes stemming from inherent design flaws in the equipment itself. For example, a specific antenna like "the Gap Titan has a serious design problem, where screws puncture the inner..." This kind of flaw, while not directly related to guy wires, highlights the broader importance of structural integrity in all components of an antenna system. A poorly designed antenna, even if mounted on a perfectly guyed mast, can still fail. This underscores the need for users to research product reliability and understand that even with robust guy wire support, the weakest link in the entire system can lead to failure. Choosing reputable manufacturers and being aware of known issues (even if anecdotal, like "worst service for European customers ever time owned" which speaks to overall brand reliability) is part of a comprehensive approach to system design and safety.

Longevity and Maintenance: Keeping Your Guy Wires Strong

Guy wires, despite their robust appearance, are subject to constant stress from wind, temperature fluctuations, and environmental factors like UV radiation (for synthetic guys) and corrosion (for steel guys). Therefore, regular inspection and maintenance are not merely recommended; they are absolutely essential for ensuring the long-term safety and performance of any guyed structure.

Routine checks should include visually inspecting all guy wires for fraying, kinks, rust, or any signs of damage. Pay close attention to termination points, turnbuckles, and anchors, as these are common failure points. Insulators should be checked for cracks or degradation. The tension of the guy wires should also be periodically verified, as temperature changes can cause expansion and contraction, altering the tension over time. Loose guy wires are ineffective, while overly tight ones can overstress the mast. Any signs of wear or damage warrant immediate attention, and replacement of affected components should be done promptly. Proactive maintenance not only extends the lifespan of your guyed system but, more importantly, prevents potentially dangerous and costly failures.

Conclusion

The humble guy wire is far more than just a piece of cable; it is the cornerstone of stability for countless vertical structures around the globe. From the specialized twists of EHS wire to the non-conductive properties of Phillystran, and the precise engineering of Rohn's guy assemblies, every component plays a critical role in ensuring safety and performance. We've explored how these essential supports counteract the relentless forces of nature, facilitate maintenance through tilt-over systems, and even influence radio frequency performance.

Understanding the nuances of guy wire systems—from proper material selection and meticulous installation to ongoing inspection and maintenance—is paramount for anyone involved with tall masts or antennas. Prioritizing quality components and adherence to best practices isn't just about optimal performance; it's about safeguarding property and, most importantly, lives. We encourage you to share your experiences with guyed mast installations or ask any further questions in the comments below. Your insights contribute to a safer, more informed community. For more in-depth guides on antenna installations and structural integrity, explore other articles on our site.

- Dorsal Foot

- Where Does Eminem Live

- Farmington Municipal Schools

- Louis Partridge Movies

- Mike Wedding Dates

What is a guy wire and how to use it? - The Ultimate Guide (2020)

What is a guy wire and how to use it? - The Ultimate Guide (2020)

What is a guy wire and how to use it? - The Ultimate Guide (2020)