Unraveling Ø: The Universal Language Of Diameter In Engineering

In the intricate world of engineering and technical drawings, clarity is paramount. Every line, every number, and every symbol carries precise meaning, leaving no room for ambiguity. Among these crucial symbols, one stands out for its widespread use and undeniable importance: the diameter symbol, often represented as Ø or ⌀. This seemingly simple mark is far more than just a circle with a slash; it's a fundamental building block of design, manufacturing, and communication across diverse industries.

From the smallest components in a micro-assembly to the largest structural elements, understanding the Ø symbol is non-negotiable for engineers, designers, and manufacturers alike. This article delves deep into the significance of this universal symbol, exploring its various applications, nuances, and the critical role it plays in ensuring precision, preventing errors, and facilitating seamless production processes. Join us as we demystify Ø and uncover its indispensable place in the realm of technical communication.

Table of Contents

- The Ubiquitous Ø: More Than Just a Circle with a Slash

- Precision in Practice: Ø in Mechanical Engineering Drawings

- The "Thru All" Imperative: Clarity in Depth

- Navigating Tolerances and Standards with Ø

- Digital Dimensions: Ø in CAD and Scripting

- Decoding Annotations: Context is Key

- From Theory to Reality: CNC Machining and the Ø Symbol

- The Enigmatic Ø: A Symbol's Journey Through Standards

The Ubiquitous Ø: More Than Just a Circle with a Slash

The diameter symbol, commonly seen as Ø or ⌀, is a cornerstone of technical drawings worldwide. Its appearance, a circle with a diagonal line through it, is instantly recognizable to anyone familiar with engineering blueprints. While it often looks similar to the lowercase letter ø (a letter found in Scandinavian alphabets), and indeed, "Looking at the Wikipedia page for ø it seems" that in some typefaces, they even share the same glyph, it's crucial to understand their distinct meanings. The diameter symbol (⌀), specifically Unicode character U+2300, is a dedicated entity for indicating diameter. As one might observe, "The diameter symbol (⌀) (unicode character u+2300) is similar to the lowercase letter ø, and in some typefaces it even uses the same glyph, although in many others the glyphs" are distinct. This distinction, while subtle in some fonts, is critical in its application. For instance, while some might debate whether "ø has a lowercase, Ø — it's the symbol for diameter ∅ that doesn't have a lowercase," the practical takeaway for engineers is that the symbol clearly denotes a circular dimension. Its inclusion in the Unicode standard ensures that "The diameter symbol is part of unicode, however, so should display on" virtually any digital platform, making it a truly global and digital-friendly standard. This universality is key to its role in precise technical communication, ensuring that a diameter specified in one country is understood identically in another.Precision in Practice: Ø in Mechanical Engineering Drawings

In mechanical engineering, the Ø symbol is not merely a notation; it's a command for precision. It dictates the exact size of circular features, from holes to shafts, ensuring components fit together as intended. Without this clear specification, manufacturing would be riddled with errors, leading to costly rework and product failures.Specifying Hole Sizes and Dimensions

One of the most common applications of the Ø symbol is in defining hole diameters. When a drawing states "Ø 5," it unambiguously means "the hole diameter (drill size) is 5mm." This level of clarity is vital for machinists who need to select the correct drill bits and tools. Consider a complex part with multiple circular features, such as those often seen in AutoCAD drawings. Annotations like "R1.25 typ (circle/hole left) 2xø1.0 (circle/hole right) ø1.25 (circle/hole bottom) based on those" provide a comprehensive overview. Here, `R` denotes a radius, while `Ø` specifies a diameter. The "2xø1.0" indicates two instances of a 1.0mm diameter hole, demonstrating how the symbol is combined with multipliers for efficiency and clarity. This precise detailing ensures that every hole is drilled to the exact specification, critical for assembly and functionality.Beyond Simple Holes: Complex Applications

The utility of the Ø symbol extends far beyond basic holes. It's used to define the diameters of shafts, pins, and even the pitch diameter of gears. For example, in a data sheet for a stepper motor, one might find that "The pitch diameter of the pinion attached to it is listed as ø6." This specifies a critical dimension for gear meshing, directly impacting the motor's performance and precision. Similarly, in electrical components, the symbol can denote wire thickness. On a technical drawing for resistors, "the lead diameter was given as φ0.55mm φ 0.55 mm." The use of `φ` here is a common alternative symbol for diameter, often seen in electrical contexts. This is further corroborated when they "also specify the wire is 24 swg, and 24 swg is a diameter of 0.559mm," confirming the precise dimension indicated by the symbol. These examples underscore how the Ø (or φ) symbol is fundamental across various engineering disciplines, ensuring that every circular dimension is communicated with absolute accuracy.The "Thru All" Imperative: Clarity in Depth

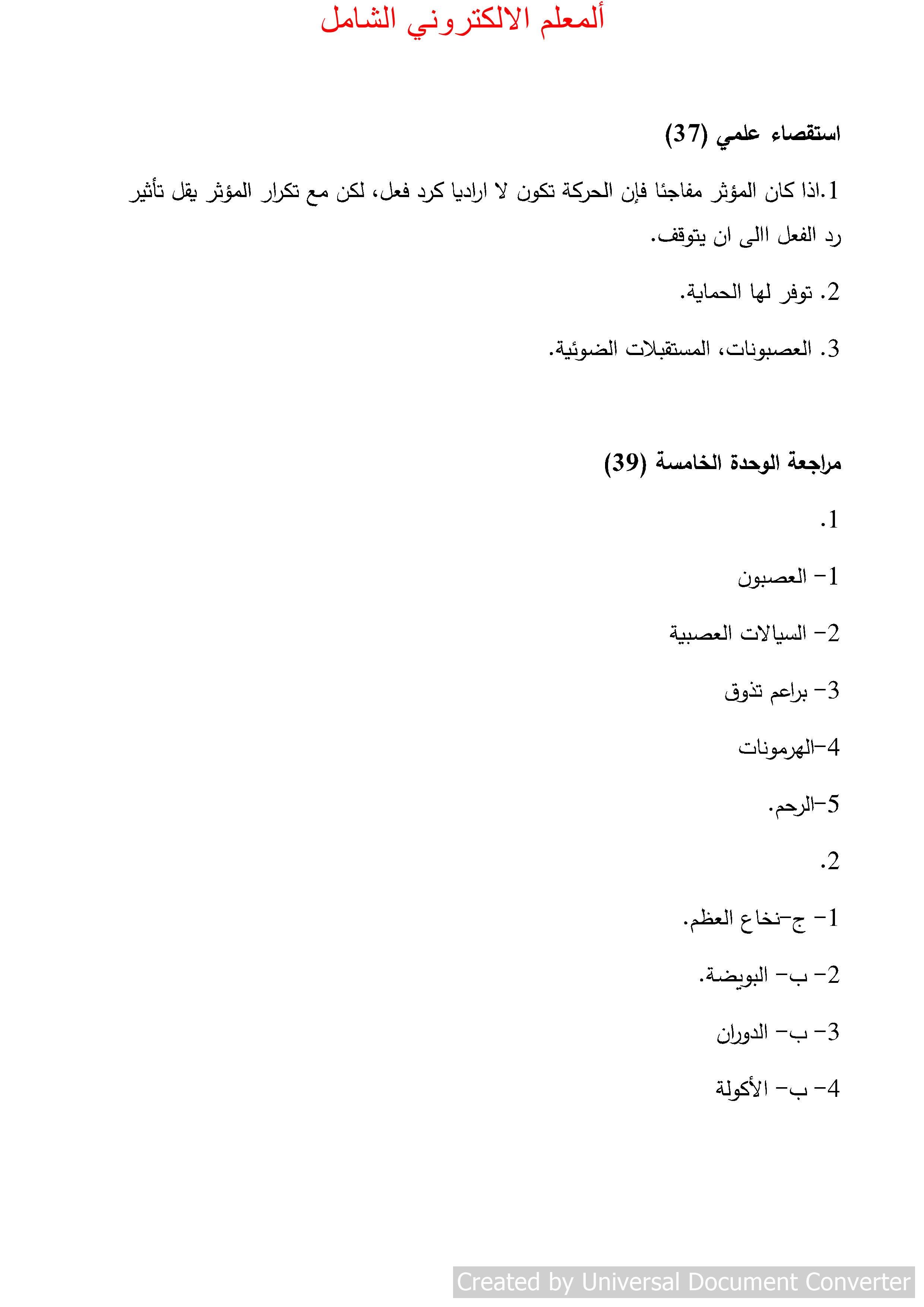

While the Ø symbol defines the diameter, specifying the depth of a hole is equally important. This is where annotations like "thru all" come into play. When "“thru all” is added here to remove the requirement for a section view to show hole depth," it provides an immediate and unambiguous instruction. Without this annotation, a drafter would typically need to create a separate section view of the part to illustrate that the hole extends completely through the material. This is because "You can’t tell by the outlines whether it’s" a blind hole (one that doesn't go all the way through) or a through hole just by looking at the primary views. By adding "thru all," the drawing becomes more concise, easier to read, and less prone to misinterpretation. This simple phrase saves significant time in both drafting and manufacturing, preventing potential errors that could arise from misjudging hole depths. It's a testament to how even small annotations contribute significantly to the overall clarity and efficiency of technical drawings.Navigating Tolerances and Standards with Ø

The Ø symbol is inherently linked to the concept of tolerances and standardized dimensions. In manufacturing, no two parts can be made exactly identical; there will always be slight variations. Tolerances define the permissible range of these variations, and the Ø symbol is crucial for specifying these ranges for circular features.Dowel Pins and Standardized Lengths

Consider the case of dowel pins, which are used for aligning parts. The question "Is the length of a steel dowel pin standardized to a certain tolerance, In the event where I" need to specify one, highlights the importance of standardized dimensions. While the diameter of a dowel pin would be specified using Ø (e.g., Ø6mm), its length also adheres to standards. "Usually the nominal length of the dowel is the total overall including the actual ground, pin section + the rounded end and + beveled end." This means that when a drawing calls for a Ø6mm x 20mm dowel pin, both the diameter and the length are understood within established industry tolerances. The Ø symbol ensures that the circular fit is precise, while the standardized length ensures interchangeability and proper alignment, critical for reliable mechanical assemblies.Edge Clearance for Tapped Holes

Another critical application where the Ø symbol interacts with design constraints is in the placement of tapped holes. When "having a tapped hole close to an edge in metal, how do you determine the minimum edge thickness around the tapped hole," it directly relates to the hole's diameter. The integrity of the material around the hole is paramount, and "Obviously the metal strength is a critical" factor. If a Ø10mm tapped hole is placed too close to an edge, the remaining material might not be strong enough to withstand the stresses of threading or the forces applied during assembly, leading to material deformation or failure. Engineers use the specified Ø of the tapped hole, along with material properties and design standards, to calculate the minimum required edge distance, ensuring structural integrity and preventing costly manufacturing defects.Digital Dimensions: Ø in CAD and Scripting

In the modern era, Computer-Aided Design (CAD) software has revolutionized technical drawing. The Ø symbol is seamlessly integrated into these digital environments, allowing for precise dimensioning and automated checks. For engineers working with software like NX or AutoCAD, extracting and manipulating these dimensions is a routine task. One might be "writing a script to extract all the dimensions from a 2d drawing in nx," and in doing so, they are able to "get the dimensions and tolerances on all sheets, along with the zone." This highlights the digital nature of the Ø symbol and its associated data. CAD systems not only display the symbol correctly but also store its associated numerical value and tolerance information, which can then be used for analysis, manufacturing automation, and quality control. The ability to programmatically access and interpret annotations like "What do the following annotations mean in this autocad drawing mean" demonstrates the power of digital design in ensuring consistency and accuracy across complex projects.Decoding Annotations: Context is Key

Beyond just specifying a single diameter, the Ø symbol often appears in conjunction with other annotations that provide crucial context. For instance, the notation "4 x" preceding a diameter specification means "it applies to the four instances that look similar on the drawing." This is a common practice in technical drawings to avoid redundant dimensioning. Instead of labeling four identical Ø5mm holes individually, a designer can simply write "4 x Ø5mm," indicating that there are four such holes. This not only makes the drawing cleaner and less cluttered but also reduces the chance of transcription errors. Understanding these contextual annotations is as important as understanding the Ø symbol itself, as they collectively form the complete instruction set for manufacturing. Misinterpreting a multiplier or a "thru all" annotation can lead to significant production errors, underscoring the need for a holistic understanding of drawing conventions.From Theory to Reality: CNC Machining and the Ø Symbol

The journey from a technical drawing to a physical part often involves Computer Numerical Control (CNC) machining. For those "quite new to mechanical engineering, but currently working on a project which I eventually want to send to a CNC service for machining," the accuracy of the Ø symbol on their drawings is paramount. CNC machines interpret the numerical values associated with the Ø symbol to precisely cut holes, turn shafts, or mill circular features. Any error or ambiguity in the diameter specification will directly translate into a flawed part. "Many services I found can" interpret these drawings, but their ability to produce the correct part hinges entirely on the clarity and accuracy of the dimensions provided. The Ø symbol serves as a direct instruction to the machine, dictating the tool path and cutting parameters. Therefore, a correctly specified Ø ensures that the final machined component meets the design intent, fitting perfectly into its assembly and performing as expected.The Enigmatic Ø: A Symbol's Journey Through Standards

While its primary role is to denote diameter, the Ø symbol, or the concept of circularity it represents, also appears in more abstract or specialized contexts. For instance, in the realm of Geometric Dimensioning and Tolerancing (GD&T), the concept of a "More accurately is defined in section 3.8 envelope requirement" often involves how circular features must conform to a perfect boundary, which is inherently tied to their specified diameters. This ensures that parts not only have the correct nominal dimensions but also meet strict form and orientation requirements for proper assembly and function. Occasionally, the Ø symbol might even appear as a variable in specific formulas, demonstrating its versatility beyond just a dimensioning callout. For example, a formula like "$$ø = \frac{2θ}{3}$$ or more generally,$$ø = \frac{2θ}{n}$$ where n = the number of hooks" suggests a scenario where `ø` represents a calculated diameter based on an angle (`θ`) and a number of elements (`n`). While this is a more specialized use case, distinct from its direct application in dimensioning, it illustrates how the fundamental concept of diameter, represented by `ø`, can be integrated into various engineering calculations and theoretical frameworks. This adaptability further solidifies the Ø symbol's status as a foundational element in the broad language of engineering.Conclusion

The Ø symbol, whether it appears as Ø, ⌀, or φ, is far more than a simple mark on a drawing. It is a universal, unambiguous language of precision, essential for conveying critical dimensional information in engineering and manufacturing. From specifying the exact size of a drill hole to defining the pitch diameter of a gear or the lead of a resistor, this symbol ensures that every circular feature is understood and produced with the utmost accuracy. Its integration into digital CAD systems, its role in defining tolerances, and its interaction with other critical annotations like "thru all" underscore its indispensable nature in modern engineering workflows. For anyone involved in design, production, or quality control, a thorough understanding of the Ø symbol is not just beneficial—it's absolutely critical for success. It prevents costly errors, facilitates seamless communication across global teams, and ultimately ensures that innovative designs can be transformed into functional, reliable products. We hope this deep dive into the Ø symbol has illuminated its profound importance. What are your experiences with this fundamental symbol? Share your insights or questions in the comments below, and explore other articles on our site to further your understanding of the fascinating world of engineering and design.- Weight Watchers Recipes

- Hakone Estate

- Suncoast Community Health Center

- Kearny Mesa Hyundai

- The Parkers Cast

Weverse - Official for All Fans

المعلم الالكتروني الشامل

المعلم الالكتروني الشامل